The North America Coiled Tubing Drilling Services market was valued at USD 2.5 billion in 2024 and is forecasted to grow to USD 4.1 billion by 2033, driven by increasing demand for enhanced oil and gas recovery, unconventional resource development, and efficient well intervention. With operators in regions like the Permian Basin and Eagle Ford Shale pushing for higher efficiency, coiled tubing has become a critical component of modern drilling operations.

Over the past decade, Tubeplus has been a trusted supplier to this market, providing seamless tubing solutions built for extremes and tailored for operators’ toughest challenges.

The Challenge in North American Oilfields

Operators in unconventional plays face several challenges:

- Complex well conditions in shale gas and tight oil formations.

- Need for efficient well interventionsto reduce non-productive time.

- Higher expectations for safety and reduced environmental impact.

Traditional tubing systems often struggle under these conditions, leading to failures, costly downtime, and higher replacement expenses.

Tubeplus ’s Oil Tool Solutions

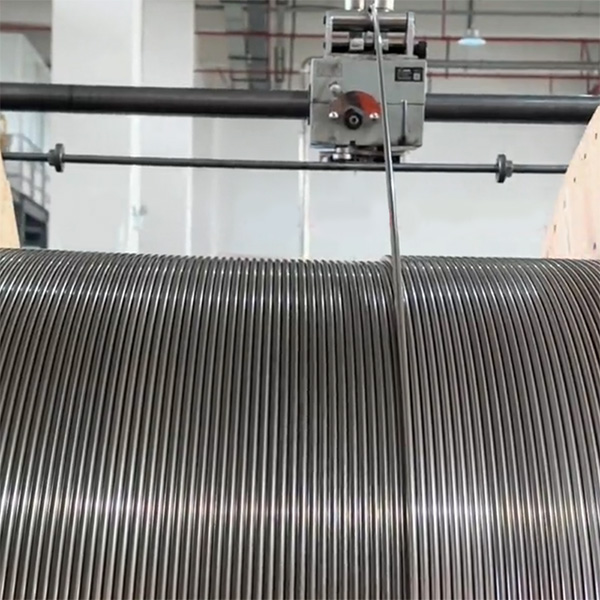

At Tubeplus , we provide more than tubing—we deliver oil tool solutions engineered to perform in the harshest environments. Our seamless tubing stands out through:

- Armor optionsfor superior abrasion and corrosion resistance.

- Multi-core configurationsfor complex well designs.

- Exceptional pulling strengthto ensure reliability during heavy interventions.

- Material flexibilityfrom stainless steel to Inconel, customized for corrosive or high-pressure wells.

Case Example: Permian Basin & Eagle Ford Shale

In the Permian Basin, operators needed tubing that could withstand extreme downhole pressure and temperature during extended coiled tubing runs. Tubeplus supplied customized seamless tubing that not only improved operational safety but also reduced non-productive time significantly.

In the Eagle Ford Shale, corrosion was a major issue. Tubeplus ’s Inconel-based seamless tubing provided the durability required, extending equipment life cycles and cutting replacement costs.

In both cases, operators praised Tubeplus for consistent product quality and reliable delivery, enabling projects to stay on schedule and meet production targets.

10 Years of Proven Reliability

For more than a decade, Tubeplus has supported North American coiled tubing drilling operations with stable supply, proven durability, and innovative designs. As the market grows—driven by real-time monitoring, automation, and environmental efficiency—Tubeplus continues to be a reliable partner for operators seeking performance-driven solutions.

Conclusion

With the coiled tubing drilling services market projected to surpass USD 4.1 billion by 2033, operators need dependable partners. Tubeplus ’s seamless tubing has already proven its value across leading oilfields like the Permian Basin and Eagle Ford Shale. By combining advanced engineering with 10 years of supply experience, Tubeplus delivers oil tool solutions that enhance efficiency, extend tubing life, and reduce operational risk.